Transforming a restaurant isn’t just about swinging a sledgehammer and putting up new walls — it’s a high-stakes puzzle where every detail matters. Every inch of framing, every kitchen exhaust vent, every twist of a gas line must be planned and priced before the first tool even leaves the truck.

One small oversight here can lead to a chain reaction: missed deadlines, inflated budgets, and unhappy clients.

That was exactly the challenge waiting for us in Elmwood Park, New Jersey, at 397 East 54th Street — a tired food service outlet that needed a complete rebirth.

This wasn’t just another renovation. It was a chance to prove why meticulous, trade-specific construction estimating isn’t optional — it’s the difference between a smooth build and a costly disaster.

In this case study, you’ll go behind the scenes of a full-service restaurant transformation — from carefully orchestrated demolition to razor-sharp coordination of structural, mechanical, plumbing, and fire protection systems. Partnering with Cardinalli Design & Architecture, P.C. and a skilled, multi-disciplinary crew, we handled every moving part under a tight, phased schedule. The result?

A masterclass in turning complex vision into reality — on budget, on time.

Understanding the Project Scope

From an estimator’s perspective, the first step is translating architectural intent into measurable, cost-driving elements.

For this project, the scope meant:

- From bare bones to brand new: Full interior demolition followed by a complete rebuild.

- A kitchen built for performance: Outfitted with 35+ major appliances, optimized for efficiency, safety, and high-volume service.

- Style meets durability: Custom finishes plus commercial-grade materials to balance aesthetics with longevity.

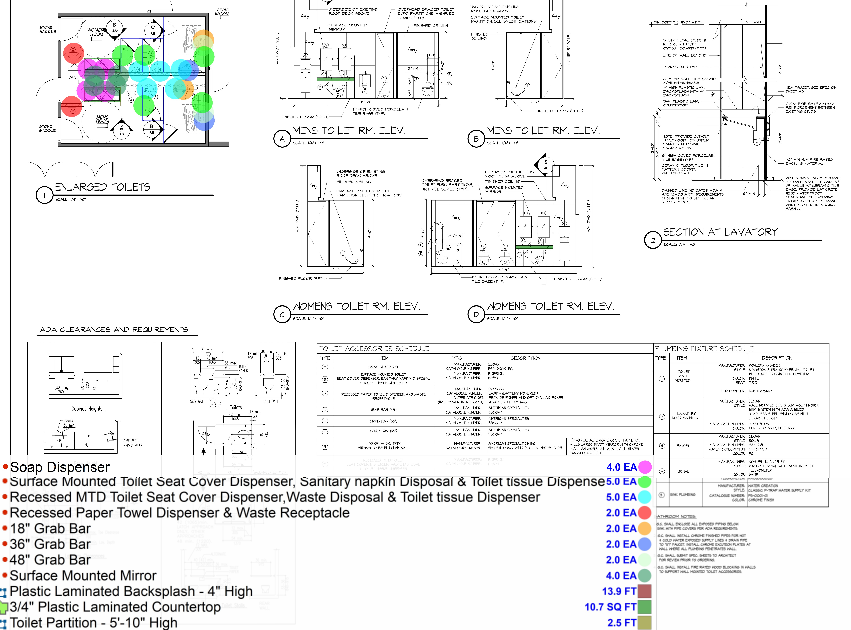

- Accessibility for all: ADA-compliant restrooms and public spaces.

- Systems in harmony: HVAC, gas, plumbing, and fire protection — all engineered to pass inspections the first time.

Budget implications included:

- Price volatility in custom millwork, specialty tile, and polished concrete.

- Skilled labor shortages for niche trades.

- Timeline risks from inspections, long-lead equipment, and trade overlaps.

Key takeaway: An accurate estimate here isn’t just math — it’s strategic risk control. If you haven’t read our commercial site development estimate case study at 131 Fort Lee Road, NJ, be sure to check it out.

Demolition Phase – Precision in Removal

Commercial demolition in a soon-to-open or active space isn’t brute force — it’s precision choreography. Every move must balance speed, safety, and code compliance.

One wrong swing can cost far more than time.

Key quantities:

- ~40 LF of 13’-8” interior partitions removed

- 6 doors removed (single and double)

- HVAC removal spanning ~7,000 sq ft

- 5,490 sq ft of ductwork dismantled

- Full removal of RTU and curb

Estimating considerations:

- Labor premiums for dust control and protecting retained structures

- Permit & inspection allowances for environmental compliance

- Mobilization costs for specialized demolition crews (HVAC, plumbing, structural)

Estimator’s insight: On projects like this, demolition alone can absorb 5–7% of the total budget.

Structural Framing & Architectural Elements

Once demolition clears the slate, framing becomes the restaurant’s backbone — defining flow, compliance, and efficiency.

Quantities:

- 1,089.4 LF of interior wall framing (multiple stud types & heights)

- Specialty furring walls for finish transitions

- 25–30 new commercial-grade doors

- Storefront glazing units, including panels >18 feet wide

Estimator’s note:

Wall height variations (9–20 ft) affect labor rates, equipment needs, and crew expertise. Flat LF pricing fails here — each wall type gets its own unit cost analysis.

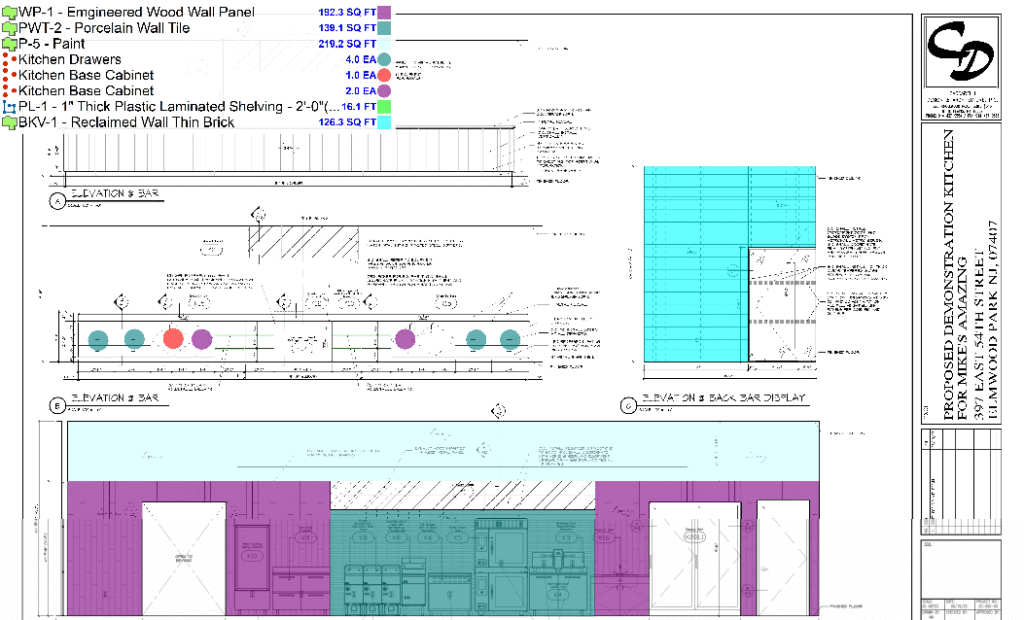

Kitchen Infrastructure – The Budget’s Core

The kitchen build-out is the most budget-intensive and technically complex phase.

Major estimating drivers:

- Installation of 35+ commercial-grade items

- Exhaust capacity exceeding 6,300 CFM across multiple fans & RTUs

- Multiple floor drains connected to grease interceptors

- Custom counters & millwork for prep and service zones

Budget impact: Kitchens typically consume 25–30% of the total budget, with a 5% reserve recommended for last-minute equipment changes.

MEP Coordination – Plumbing & Gas

Plumbing and gas systems here were no simple connections — they were intricate lifelines.

Scope:

- 337+ ft of gas piping (½”–2”), with solenoid valves, regulators, shutoffs

- 400+ ft of copper water piping with backflow preventers & mixing valves

- Cast iron sanitary lines, grease interceptor, condensate management

Challenges:

- Multi-trade overlap in tight spaces

- Phased riser installs across multiple levels

- Redundant shutoffs and cleanouts for code compliance

Why it matters: Tight working conditions = slower progress and higher labor costs. The estimate must reflect this reality.

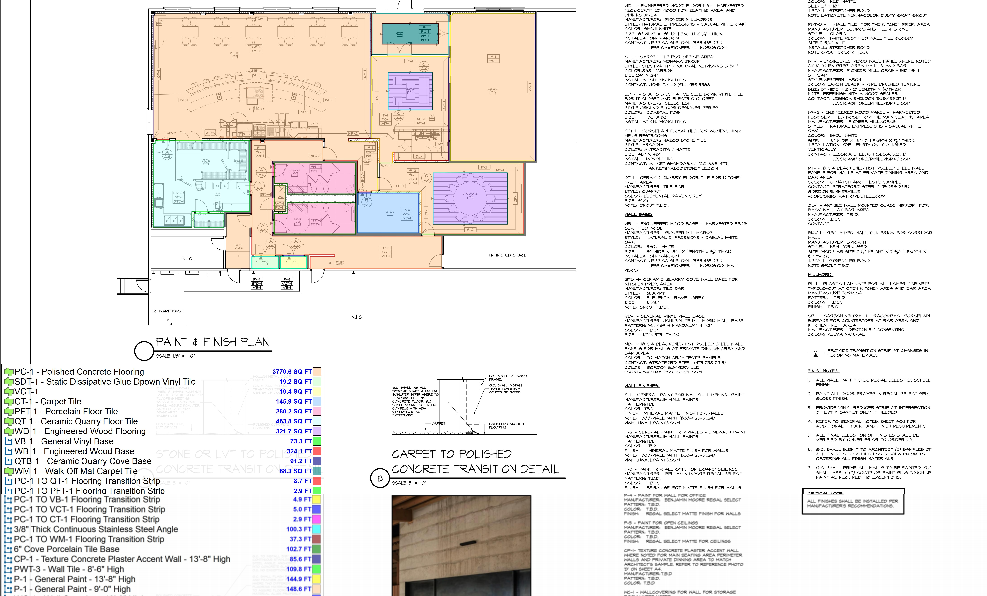

Ceilings, Flooring, and Finishes

This is where the restaurant’s brand personality meets the budget.

Details:

- 4,900+ sq ft of ceilings (ACT tiles, suspended wood, GWB, metal panels, exposed sections)

- 3,770 sq ft polished concrete, plus specialty tile and static-dissipative flooring

- Walls with porcelain tile, reclaimed thin brick, engineered wood panels

Estimator’s insight: Multiple finish types mean more complexity, more setups, and more waste — each gets its own detailed budget line.

Contingencies & Risk Management

A solid contingency plan protects against unforeseen costs.

Built-in buffers:

- Base contingency: 10% for standard unknowns

- Kitchen integration: +5% for design or equipment changes

- Schedule buffer: 15% for permitting and inspection delays

For a $1.5M project: $150K base + $75K kitchen reserve = budget protection against surprises.

Phase-Based Costing – Accuracy Over Assumptions

Generic $/sq ft pricing is dangerous here.

We used a phase-based cost allocation to account for:

- Demolition & Site Prep – Selective demo, MEP disconnects, heavy HVAC removal, dust control, debris hauling.

- Structural & Rough Construction – Wall framing, storefront work, steel adjustments, rooftop HVAC supports.

- Kitchen Equipment & Infrastructure – Hood systems, gas, refrigeration, drainage, and equipment rigging.

- Finishes – Flooring, ceilings, wall treatments, millwork, and paint.

- Final Systems & Cleanup – MEP testing, commissioning, fire system checks, punch lists.

Estimator’s check: Compare allocations to trade takeoffs and historical data. If a phase looks off, dig before you commit.

Balancing Labor and Material Costs

The material-to-labor ratio shifts by trade:

- Plumbing & Gas – High material cost (copper, cast iron) + overhead work increases labor.

- HVAC – Large equipment plus challenging rooftop installs = high material and labor.

- Finishes – Labor-heavy for precision craftsmanship.

- Kitchen Equipment – Gear is expensive, but installation labor can surprise you.

Example: Installing a 19-foot wall needs lifts, harnesses, and slower work than an 8-foot wall — factor this in, or your estimate could be off by 10–15%.

The Role of Multi-Trade Coordination

Scheduling trades is as critical as pricing them.

Considerations:

- Plumbers & electricians must rough-in before walls close.

- HVAC ducts can dictate ceiling height.

- Gas lines must align with cooking station layouts.

- Fire sprinklers must clear hoods and lighting.

Estimating for coordination means adding:

- Standby allowances for delayed trades

- Remobilization costs

- Overtime premiums to recover schedule slips

Compliance as a Cost Factor

Code compliance directly affects costs:

- ADA: Grab bars, clearances, custom fabrication for fixtures

- Health Dept: Grease interceptors, washable surfaces, prep/cooking separation

- Fire Safety: Correct sprinkler head spacing and ratings

Missing these in the estimate means costly change orders later.

Contingency Planning in Real Numbers

While some owners resist higher contingency rates, this complexity demanded:

- 10% base

- 5% kitchen-specific

- 15% schedule buffer

On $1.5M, that’s $225K in reserves — the shield against delays, equipment lead times, and unforeseen demo issues.

Conclusion – Why This Approach Works

In commercial restaurant construction, estimating isn’t just about numbers — it’s about foresight.

It’s where design dreams meet real-world constraints, and where proactive planning can mean the difference between profit and pain.

The Elmwood Park renovation proves that:

- Detailed takeoffs prevent budget blind spots

- Realistic labor allowances keep crews productive

- Multi-trade risk planning avoids costly schedule disruptions

Ready to Protect Your Budget and Maximize Your Build?

Whether you’re an owner, contractor, or developer, precision estimating turns uncertainty into profit.

Let’s talk about how we can help you:

📞 Contact us today to discuss your upcoming project

📧 Request a detailed estimate now — and build with confidence from day one.