When it comes to commercial construction, there’s no room for guesswork. A single slip in plumbing estimation—be it a miscounted pipe length or an overlooked fixture—can snowball into skyrocketing costs, painful delays, and even compliance nightmares. That’s why accurate estimating isn’t just about numbers; it’s about building confidence, control, and clarity before the first trench is dug.

In this case study, we take you inside the Babcock Ranch B Street Retail Core project in Punta Gorda, FL—an ambitious development spanning eight commercial buildings (B Street is set to showcase a dynamic mix of dining, retail, commercial, office, and residential spaces, creating a vibrant community hub). From water supply and gas distribution to sanitary sewer, grease waste, and ventilation systems, every utility had to be mapped with precision. Our client, Joseph, needed more than just a cost figure—he needed a detailed roadmap covering material takeoff, labor breakdowns, infrastructure planning, scheduling, and risk management.

Need accurate plumbing cost estimates for your next commercial project? Hire Utopian TakeOffs for precise takeoffs that save time, money, and risk. We also bring the same expertise to electrical work—see our electrical estimation at Tampa Executive Airport, Florida.

Table of Contents

Babcock Ranch Plumbing Estimation Project Overview – Scope & Challenges

- Location: Babcock Ranch B Street Retail Core, Punta Gorda, FL 33982

- Project Type: Commercial Plumbing & Utility Systems

- Scope: Eight buildings with multi-level plumbing infrastructure

- Client Name: Joseph

- Estimator’s Role: Utopian Takeoffs Provide detailed cost estimation, material breakdown, and construction sequencing

Key Challenges in Commercial Plumbing Estimation – Risks & Cost Drivers

Plumbing a massive commercial project isn’t just about pipes and fittings—it’s a puzzle with countless moving parts, each one critical to getting it right.

- Multi-system integration: This project wasn’t just about laying pipes—it meant weaving together water, gas, sewer, and grease waste systems into one seamless network without a single clash.

- Elevations and risers: With piping stretching from ground level to over 778 feet, vertical distribution became a cost-critical challenge that demanded laser-focused precision.

- Future-proofing: Built for today but ready for tomorrow—tenant-ready connections, caps, and stubs were factored in to save future headaches (and costs).

- Specialized fixtures: From ADA-compliant restrooms to thermostatic mixing valves, grease interceptors, and roof hydrants, every specialty item carried unique cost and installation considerations.

- Code compliance: In Florida, cutting corners isn’t an option. Every system had to meet state plumbing codes and building standards, ensuring safety, efficiency, and long-term reliability.

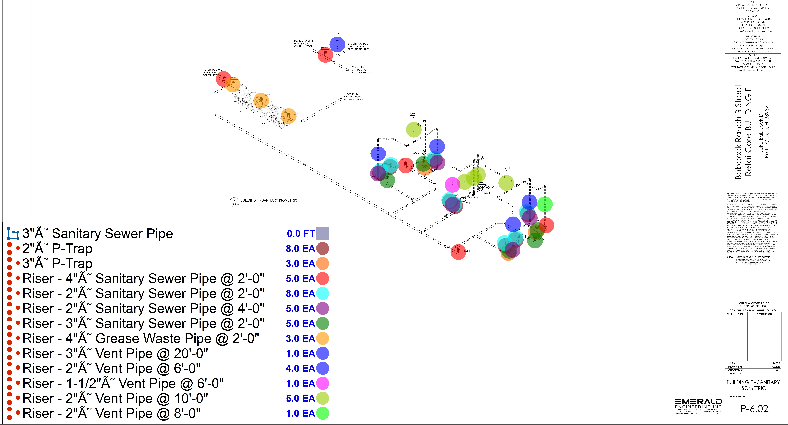

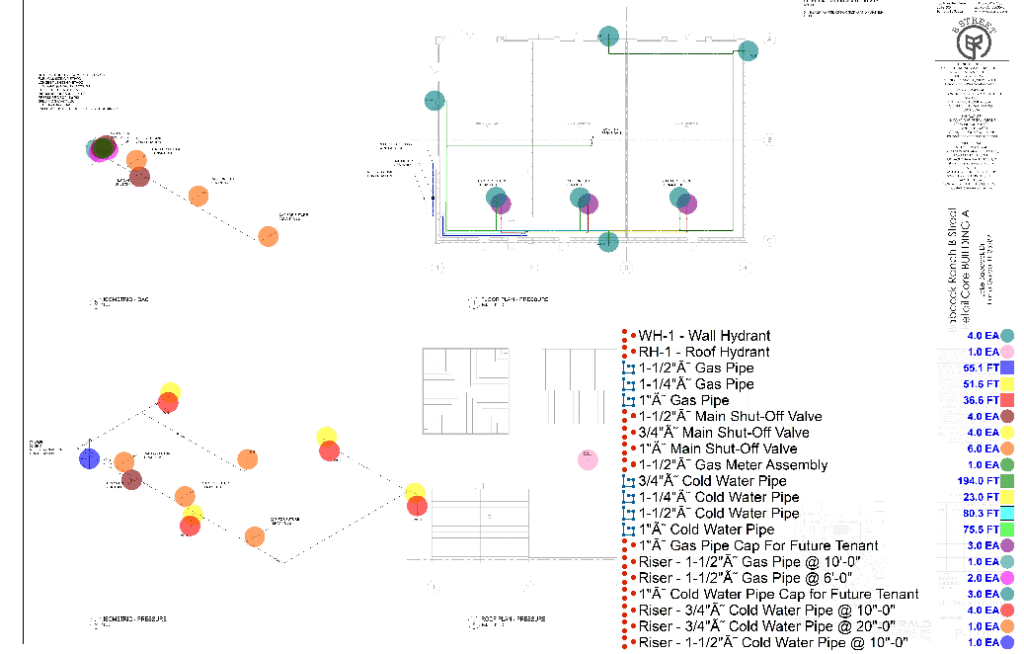

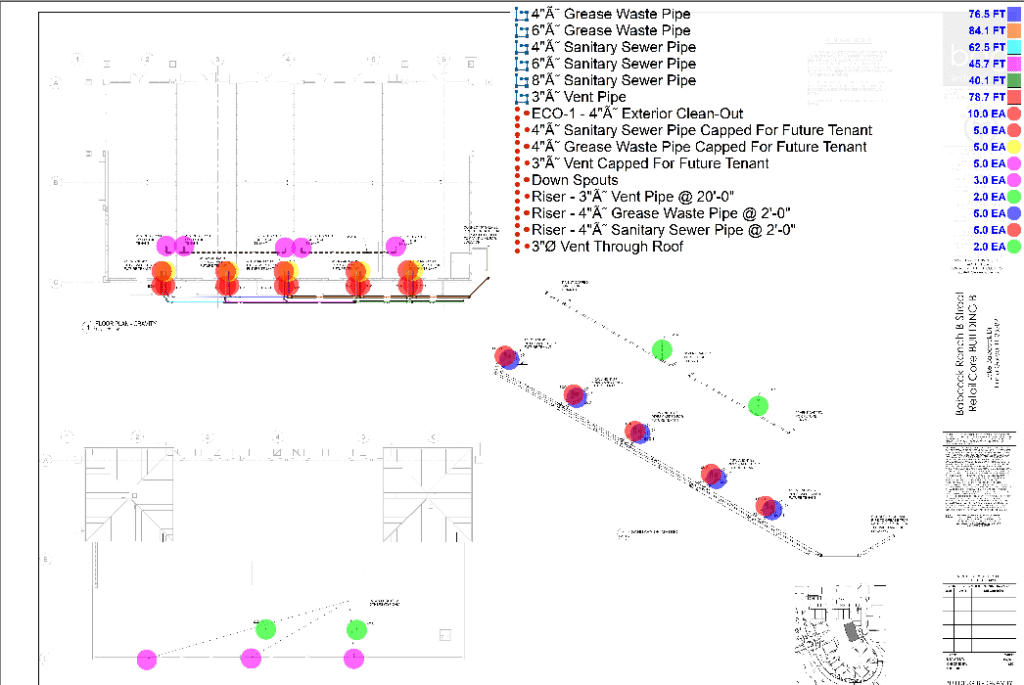

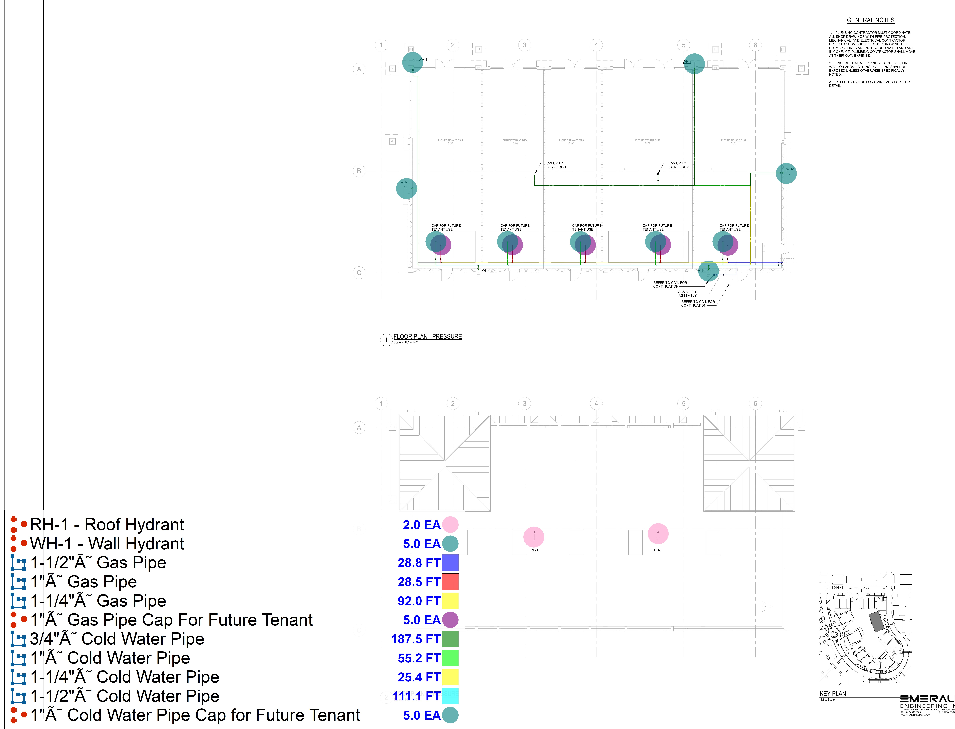

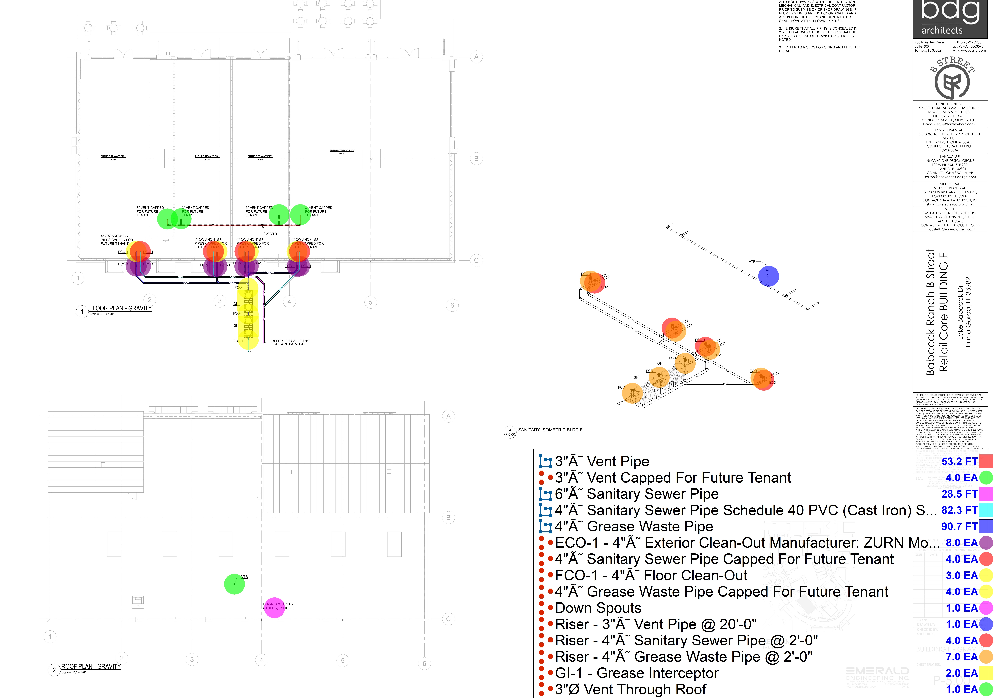

Inside the Plumbing Plans – How We Turned Utility Blueprints into Cost Certainty

The utility plans weren’t just drawings—they were blueprints of precision. Every detail was mapped out: color-coded diagrams, pipe sizes, material specs, and elevations. As estimators, we didn’t just glance—we dissected each system one by one, uncovering the true cost story hidden in the lines.

1. Water Supply System

- Cold and hot water distribution networks

- Pipe sizes from ½” to 1-¼” copper lines

- Roof and wall hydrants (RH-1, WH-1)

- Riser assemblies at multiple elevations

- Shut-off valves and future tenant water connections

2. Gas Distribution System

- Gas pipes that stretched from ½” to 2” steel—built tough, both welded and seamless.

- Heavy-duty gas meter assemblies and main shut-off valves to keep the system secure.

- Future-ready gas caps for tenants, ensuring smooth expansions without extra hassle.

- Connections climbing as high as 778.8 FT—powering a massive multi-story infrastructure.

3. Sanitary Sewer System

- Pipe sizes from 1-½” to 6”

- Floor drains, clean-outs, and P-traps

- Vent-through-roof (VTR) connections

- Multiple elevations for distribution

4. Grease Waste System

- 3”–4” grease waste lines

- Grease interceptors connected to kitchen and restroom facilities

- Specialized drainage integration for food-service tenants

5. Ventilation Network

- Vent pipes from 3” to 6” diameter

- Roof penetrations for proper airflow and odor control

- Vertical risers tied to sanitary and grease waste systems

6. Specialized Fixtures

- ADA-compliant water closets

- Lavatories, thermostatic mixing valves, electric water coolers

- Downspouts and wall hydrants

Utopian TakeOffs Estimator’s Approach – Step-by-Step Plumbing Estimation for Accuracy & Savings

As construction estimators, our process was divided into four key phases:

1. Material Takeoff (MTO)

We rolled up our sleeves and pulled a detailed material takeoff straight from the plumbing drawings. Here’s what went into it:

- Pipes by the foot – Every inch of water, sewer, vent, and gas line carefully counted.

- Fittings & valves – From shut-off valves to riser assemblies and clean-outs, nothing missed.

- Special gear – Grease interceptors, thermostatic valves, and hydrants factored in.

- Future-ready – Caps, stubs, and connections set aside for upcoming tenants.

It’s not just a takeoff—it’s a roadmap for precision and cost control.

2. Labor Cost Estimation

Plumbing labor isn’t one-size-fits-all—every task moves at its own pace. Here’s what we considered

- Pipe installation (copper, steel, PVC) at varying elevations

- Specialized fixture installation (ADA, grease interceptors, hydrants)

- Vent-through-roof penetrations requiring additional labor hours

- Coordination with electrical and HVAC crews to prevent conflicts

3. Utility Infrastructure Costing

Utility plans are multi-layered, meaning costs had to be broken down system by system.

- Water distribution vs. gas line installation

- Sanitary sewer vs. grease waste handling

- Roof hydrant vs. wall hydrant cost differentials

- Long-term maintenance considerations factored into lifecycle cost analysis

4. Scheduling & Risk Management

- Critical Path Planning – Sewer and water systems sequenced before interior finishes.

- Material Lead Times – Factoring in copper pipe procurement vs. steel welding availability.

- Risk Watchlist – Permit delays, weather impacts, and inspection hurdles.

- Built-in Safeguards – Contingency allowances to handle rework without derailing progress.

Smart planning turned potential roadblocks into smooth progress.

Key Plumbing Estimation Insights – What Really Drives Project Costs

Plumbing a big project isn’t just about pipes—it’s about strategy, costs, and smart planning. Here’s what really drives the numbers:

- Vertical Challenges – Tall risers (up to 778 FT) mean higher labor and material costs.

- Future-Proofing – Pre-installed stubs and caps save future headaches but raise today’s budget.

- Grease Waste Systems – Interceptors and 4” pipe networks cost far more than standard sanitary lines.

- ADA Compliance – Specialized fixtures are pricier, but absolutely required for retail spaces.

- Trade Coordination – Plumbing must align perfectly with HVAC, electrical, and structural work to avoid costly rework.

In short, every detail matters—and smart planning upfront prevents expensive surprises later.

Benefits of Professional Plumbing Estimation – How Joseph Gained Confidence & Control

For Joseph, the client, professional estimating provided:

- Clear financial roadmap – Every system broken down with transparent costs.

- Reduced risk – Potential overruns flagged early in design, before they snowballed.

- Accurate budgeting – Labor and material costs matched to real Florida market rates.

- Improved scheduling – Smart sequencing kept delays off the table.

- Future-proofing – Tenant-ready connections added long-term value from day one.

The result? Confidence, control, and a retail complex built for both today and tomorrow.

Detailed Plumbing Cost Analysis – Materials, Labor & Risk Breakdown

Estimating plumbing for a commercial project goes way beyond counting pipe sizes. It’s about turning blueprints into real, reliable numbers. For the Babcock Ranch Retail Core, we made it simple—breaking the estimate into clear cost categories that told the full story.

1. Material Required

Materials form the backbone of any plumbing system, and this project required a wide range of components:

- Water Supply Materials

- Copper pipes: ½”–1¼”

- Shut-off valves, risers, wall hydrants, and roof hydrants

- Caps and fittings for future tenant connections

- Gas Distribution Materials

- Welded and seamless steel pipes: ½”–2”

- Gas meter assemblies and main shut-off valves

- Fittings, soldered joints, and future gas caps

- Sanitary Sewer & Grease Waste Materials

- PVC pipes: 1½”–6”

- Floor drains, clean-outs, and P-traps

- Grease interceptors and grease waste lines

- Ventilation Materials

- Vent pipes: 3”–6”

- Roof penetrations and vent-through-roof assemblies

- Specialized Fixtures

- ADA-compliant lavatories and water closets

- Thermostatic mixing valves

- Electric water coolers and downspouts

Material costs accounted for 45–50% of the total plumbing budget.

2. Labor Costs

Labor is the game-changer—get it wrong, and costs can spiral fast. For this project, we broke labor down into clear categories to keep everything on track:

- Pipe installation crews (copper, steel, and PVC systems)

- Specialized fixture installation teams for ADA and grease interceptors

- Skilled welders for gas line assembly

- General laborers for excavation, backfilling, and clean-outs

Factors influencing labor costs:

- Multi-level piping: Reaching heights of 778 FT meant scaffolding and lifts were a must.

- Tight coordination: Sharing space with HVAC and electrical crews slowed productivity.

- Strict inspections: Florida codes demanded extra hours for inspections and rework allowances.

👉 Labor made up 35–40% of total plumbing costs.

3. Utility & Permitting Costs

A project of this scale required:

- Permitting fees for water, gas, and sewer connections

- Utility tie-ins to municipal lines

- Testing & inspection fees (pressure testing, vent inspections, grease interceptor checks)

👉 Utility and permit costs made up 10–12% of the overall budget.

4. Contingency & Risk Allowance

Commercial plumbing comes with its fair share of surprises. To stay ahead, we built in a 5–7% contingency to cover:

- Material price fluctuations (especially copper and steel)

- Weather-related delays in Florida’s humid climate

- Potential design changes requested by tenants

Plumbing Estimation Lessons from Babcock Ranch – Smarter Planning for Contractors

Every project teaches something new—and this one was no exception. Here are the key takeaways that sharpen future estimates:

- Plan for the future: Adding caps and risers upfront saved disruptions later and boosted retail appeal.

- Height = complexity: Multi-story risers meant higher labor and safety costs than flat installs.

- Don’t forget grease waste: Food tenants required costly interceptors and waste systems.

- Teamwork pays off: Coordinating with HVAC and electrical trades cut rework and delays.

- Details matter: A precise material takeoff kept the budget on point—even for small items like valves.

Best Practices in Commercial Plumbing Estimation – How to Cut Costs & Avoid Risks

Plumbing estimates can make or break a project. Here’s how to keep your numbers sharp, realistic, and future-proof.

1. Nail the Material Takeoff

Count everything—valves, fittings, hydrants. Don’t skip future tenant provisions like stubs, caps, and risers. And remember specialty gear: ADA fixtures, mixing valves, clean-outs.

2. Plan for Vertical Work

High-rise = higher costs. Adjust labor for elevated floors, add scaffolding and lifts, and prepare for slower progress in tight utility shafts.

3. Estimate with the Schedule in Mind

Sequence matters—sewer and water first, finishes last. Build in inspection time, city utility delays, and trade coordination to stay on track.

4. Don’t Overlook Code & Compliance

Building codes can hit your budget hard. From ADA fixtures that need special installs, to grease interceptors in kitchens, to roof penetrations that demand extra sealing and inspections—compliance always comes with a price tag.

5. Always Add Contingency

Plumbing is unpredictable. Material costs swing, inspections trigger rework, and surprises pop up mid-project. A smart 5–7% contingency keeps your budget flexible and your project stress-free.

How Utopian TakeOffs’ Professional Estimating Transformed the Babcock Ranch Project

Joseph, this wasn’t just a plumbing estimate. For Joseph, the plumbing estimate went far beyond costs—it gave him a clear roadmap to manage budget, risks, and timelines. With every detail accounted for, he could move forward confidently, knowing investors and stakeholders were fully aligned.

- Budget clarity: Every dollar for materials, labor, and permits mapped out

- Lower risk: Challenges like vertical runs and tenant tie-ins priced upfront

- Smarter planning: Sequencing aligned smoothly with other trades

- Investor trust: A transparent estimate that built real confidence

Conclusion – Why Smart Plumbing Estimation Protects Budgets & Timelines

The Babcock Ranch B Street Retail Core shows just how crucial estimating is in big commercial builds. With eight buildings, complex utilities, and future tenant needs, precision was everything. We turned technical plumbing plans into a clear cost roadmap—covering materials, labor, scheduling, and risks. In the end, it wasn’t just about pipes; it was about protecting the project’s budget, timeline, and long-term success.

Key takeaway: Smart plumbing estimating doesn’t just cut costs—it keeps the whole project on track. And if you’re looking to take that same precision beyond plumbing into MEP systems, explore our MEP construction estimation services to ensure your next project runs efficiently from start to finish.

Request a Call Back from Our Experts

Provide your details and our team will prepare a tailored construction takeoff/estimate for you.