Electrical Estimation at Tampa Executive Airport

One of my most exciting projects as a construction estimator was handling the electrical installation for a private hangar at Tampa Executive Airport, Florida. Unlike typical residential or commercial jobs, aviation facilities demand stricter safety, compliance, and technical precision. In this case study, I’ll share how we broke down the blueprints, structured a step-by-step estimation, and tackled unique requirements—from power distribution to aviation-grade systems—ensuring accuracy, efficiency, and full compliance.

Utopian Takeoff Construction Estimation Services

At Utopian Takeoffs, we specialize in delivering precise, risk-aware construction estimating services that help contractors, developers, and private clients win more bids and execute projects with confidence. By combining advanced digital takeoff tools with expert human insight, we ensure every detail—from electrical systems to structural components—is quantified accurately. Our estimates don’t just save you time and money; they give you a clear roadmap for success, reducing risks, safeguarding timelines, and keeping you competitive in today’s fast-paced construction market.

Table of Contents

Projects Details

- Project Location: Tampa Executive Airport, Florida

- Project Type: Electrical Installation – Private Hangar

- Project Address: 6530 Tampa Executive Airport Road, Seffner, FL 33584

- Client Name: Rodrigo

Understanding the Project Scope

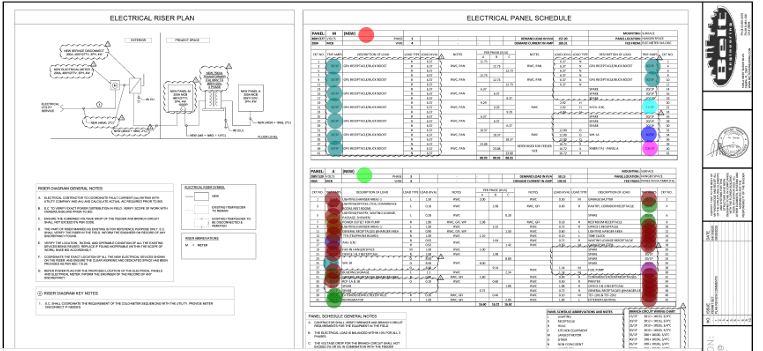

Every great estimate starts with a deep dive into the scope—and this private hangar project was no exception. The electrical drawings (E-2.1 Power Plan, E-3.1 Distribution Details, and E-4.1 Grounding Systems) became our roadmap, outlining the complexity of the work ahead.

Here’s what the project demanded:

- Lighting Systems: A full network of LED fixtures—recessed, task, emergency lights, and exit signs.

- Electrical Distribution: A robust 480V/277V three-phase system with multiple panels, breakers, and branch circuits.

- Grounding Systems: Dedicated telecom grounding, copper bus systems, and bonding jumpers for safety and compliance.

- Low-Voltage Systems: Communication cabling designed to cover the entire hangar.

By dissecting these elements, we shaped a precise installation plan, ensuring every phase aligned with the client’s needs, industry standards, and operational efficiency.

Why Blueprint Analysis is the Backbone of Electrical Estimating

Too often, estimators rush into crunching numbers—but the real success lies in blueprint analysis. Before a single cost is calculated, the drawings reveal the project’s true demands and hidden risks. For contractors and project owners, this step delivers huge value by:

- Identifying Requirements: Pinpointing every fixture, panel, and circuit the project calls for.

- Verifying Compliance: Ensuring alignment with NEC standards and local codes.

- Planning Productivity: Mapping labor hours for rough-in, installation, and final commissioning.

- Managing Risks: Flagging ceiling height issues, conduit routing conflicts, or hazardous zones early.

In our private hangar project, this blueprint review was the bridge between the engineer’s design intent and the estimator’s execution plan—making sure no critical detail slipped through the cracks.

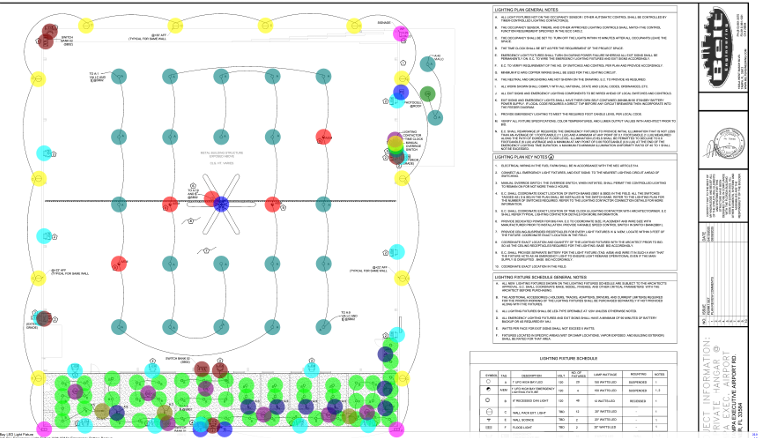

Lighting Systems – Beyond Illumination

Lighting is often the most visible part of any electrical project, and in a hangar environment, it plays a critical role in safety and functionality. The blueprint called for:

- Recessed LED fixtures (the majority of general lighting)

- Emergency lighting units to provide backup illumination during outages

- Exit lighting systems to guide occupants to safe egress routes

- Task lighting in designated areas where precision work may be carried out

Each type of lighting was marked on the drawings with color-coded indicators, which allowed us to quantify and classify the fixtures efficiently.

From an estimator’s standpoint, lighting analysis is about more than fixture counts. It requires considering:

- Circuit loading to avoid overloading breakers.

- Control strategies such as switching zones, dimmers, and automated occupancy sensors.

- Energy efficiency compliance, especially since Florida building codes emphasize sustainable systems.

By incorporating LED technology with advanced controls, this project not only ensured energy savings but also reduced long-term maintenance for the client.

Power Distribution – The Heart of the Electrical System

In a facility like this, power distribution isn’t just important—it’s everything. The electrical design called for a 480Y/277V three-phase, four-wire system feeding multiple panel boards. This configuration gave the hangar the muscle to run heavy-duty aviation equipment while seamlessly supporting everyday needs like lighting and general circuits. In short, the system was engineered to deliver reliability, flexibility, and performance—exactly what an active hangar demands.

Key components of the distribution system included:

- Main Electrical Panels – Sized to handle aviation facility loads.

- Circuit Breakers – One-pole, two-pole, and three-pole breakers of varying amperages.

- Feeder Conduits and Conductors – With conductors like #3/0 copper and grounds installed in EMT conduits.

- Branch Circuits – Using #12 AWG copper conductors for lighting and device circuits.

When it came to estimating this hangar’s electrical systems, every detail mattered. Conductor lengths, conduit sizes, and breaker counts had to be spot-on—especially for feeders stretching across the hangar with both long horizontal runs and tricky vertical risers.

But it wasn’t just about today’s needs. Aviation facilities are built to evolve, so our estimate also factored in future expansion capacity. By planning extra panel space and properly sized conduits, we ensured the client could grow without facing costly redesigns or rework later.

Grounding and Safety Systems

Grounding is a cornerstone of electrical safety, especially in aviation environments where sensitive equipment and high-power systems coexist. The drawings included:

- Telecommunication grounding bus for data and comm systems.

- Building ground bus with insulators connected to the structure.

- Bonding jumpers to maintain continuity.

- Copper grounding electrode conductors linked to rods driven into the earth.

For an estimator, grounding is never just another checkbox—it’s the lifeline of both safety and compliance. Skip it, and the hangar’s entire electrical system could face dangerous surges, costly equipment failures, or even personnel risks. That’s why this blueprint stage demanded precision: from calculating exact material takeoffs for conductors, rods, and connectors to mapping labor needs for terminations and testing. Every detail had to align to keep the system—and everyone in it—protected.

Communication & Data Systems

Modern aviation facilities don’t just run on power—they run on data. In this project, the electrical plans revealed over 1,200 feet of communication cabling routed to outlets across the hangar. This infrastructure wasn’t an afterthought; it was the backbone for seamless operations, connecting systems, equipment, and personnel to keep the facility running smoothly and efficiently.

Low-voltage estimating is unique because it requires balancing:

- Cable lengths and routing (avoiding interference with power runs)

- Device placements (outlets, risers, and network points)

- Integration with telecom vendor systems

For the client, this meant having a future-ready hangar that could support everything from basic office networking to advanced aircraft management systems.

This project wasn’t just about delivering electricity—it was about ensuring seamless connectivity. By analyzing the communication systems in the blueprint, we aligned power with data flow to create a more efficient, future-ready hangar.

Labor Planning and Phasing

With the electrical plan defined, the next step was labor planning. For this hangar, we built a three-phase strategy aligned with the construction schedule to keep the project efficient and on track.

Rough-In Installation

Key tasks included:

- Running conduit pathways across the facility

- Pulling feeder conductors and homerun circuits

- Setting panel boards and distribution equipment

This phase required the most labor hours, as conduit and wire pulling in large hangar spaces meant long, demanding runs.

Finish Installation

- Mounting fixtures, installing devices, and terminating branch circuits.

- Setting up lighting controls, switches, and emergency systems.

- Integrating communication cabling outlets.

This phase is about precision—ensuring each device is installed at the right height, every fixture aligned, and all systems tested for functionality.

Testing & Commissioning

- Testing each circuit for continuity and safety.

- Verifying emergency lighting and exit signs.

- Commissioning panels and ensuring compliance with NEC requirements.

This is the final stage before handover, and while it requires fewer labor hours, it is crucial for quality assurance and inspection approvals.

Breaking the work into clear labor phases paid off. It gave us a predictable schedule, cut down on downtime, and offered the client full transparency on progress and productivity.

Risk Management in Electrical Estimating

Every project has risks—but in aviation, the margin for error is razor-thin. My role as an estimator isn’t just about tallying up materials and labor; it’s about predicting the pitfalls that could derail cost, schedule, or quality. That proactive foresight is what keeps a complex hangar project running smoothly from blueprint to completion.

Some key risks we identified included:

On a project like this hangar, risk management was just as important as the estimating itself. Some of the biggest challenges included:

- Site Conditions: Existing infrastructure could block conduit runs, requiring redesigns or costly modifications.

- Ceiling Heights: Tall hangar ceilings meant extra planning for lifts, safety, and longer labor times during fixture installs.

- Hazardous Classifications: With fuel storage and maintenance, parts of the hangar risked falling under Class I Division 2, demanding specialized conduit, fixtures, and wiring.

- Material Escalation: Volatile prices for copper conductors, LED drivers, and panels meant careful budgeting and contingencies.

- Labor Availability: Skilled electricians in Florida are in high demand, so scheduling and resource planning were critical to keep delivery on track.

Anticipating these risks early allowed us to build a plan that balanced safety, compliance, cost, and schedule.

Compliance with Codes and Standards

Aviation facilities like private hangars must comply with strict safety and regulatory standards. This project’s electrical design was guided by:

- National Electrical Code (NEC) – Ensuring proper conductor sizing, breaker selection, and grounding.

- Local Florida Building Code (FBC) – With a focus on energy efficiency and sustainable systems.

- Emergency and Egress Standards – Mandating reliable emergency lighting and illuminated exit signage.

- Grounding and Bonding Requirements – Critical in a hangar setting where sensitive communication equipment and high-power electrical systems coexist.

For an estimator, compliance isn’t paperwork—it shapes everything. From choosing UL-listed fixtures and conductors to planning labor for grounding that passes depth and continuity tests, every detail matters. When estimation aligns with code, inspections run smoothly, risks of rework disappear, and both contractor and client stay protected from costly setbacks.

Why Professional Estimating Makes a Difference

For clients like Rodrigo, the true benefit of working with a professional construction estimator like Utopian Takeoffs lies in accuracy and foresight. Electrical systems in aviation facilities are complex, and mistakes in planning can result in delays, inspection failures, or unsafe installations.

By performing a comprehensive electrical estimating process, we:

- Ensured that material quantities matched the design intent.

- Anticipated labor hours with realistic productivity factors.

- Flagged potential risks early and recommended mitigation strategies.

- Delivered a project timeline that aligned with the overall construction schedule.

This level of detail gave the client confidence in both the design and the execution plan.

Conclusion-Electrical Estimation at Tampa Executive Airport Florida

This Tampa Executive Airport hangar case study shows how expert blueprint analysis and precise estimating turn a complex aviation project into a streamlined, code-compliant, and future-ready facility. From lighting to power distribution, grounding, and communication systems—every detail was phased, planned, and executed with accuracy. And it’s not just electrical—our work on plumbing estimation at Babcock Ranch in Punta Gorda, Florida shows the same precision applied across other critical trades.

The takeaway is simple: professional estimating isn’t a cost—it’s an investment. It reduces risk, ensures compliance, and keeps timelines on track.

Planning an aviation, residential, commercial, or industrial project? Partner with a professional estimator who can transform your blueprints into a winning execution plan. For contractors working on homes, our Residential Construction Estimating in Florida guide shows how the same precision applies to residential projects as well.