Project Brief

When Mike from Allied Universal came to us with demolition plans for the 5th floor of their NYC office at 123 William Street, we knew right away this wasn’t going to be a simple tear-down. This was a 15,000 sq. ft. interior demolition project inside a bustling commercial building—meaning every detail mattered. From accurate estimating to smart sequencing and careful risk management, this job required expertise at every step.

Demolition Estimating Services

As the construction estimator on this project, my job wasn’t just crunching numbers—it was turning a stack of complex demolition drawings into a clear, actionable roadmap. From predicting costs to mapping logistics, every detail had to be precise. Here’s how we broke it down step by step to keep the project on budget and on track.

Table of Contents

Understanding the Scope

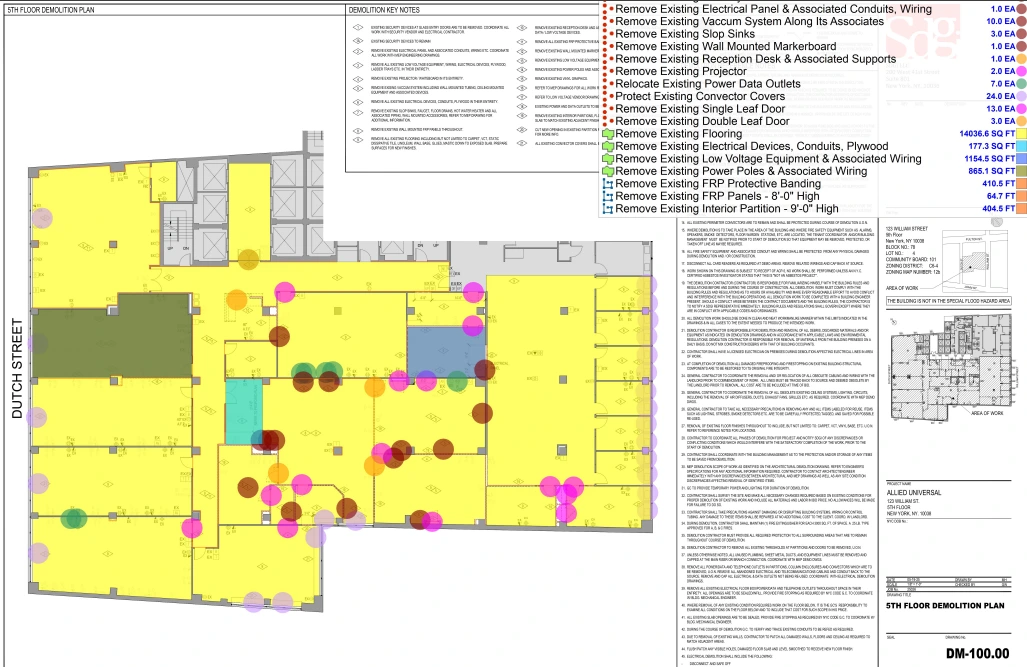

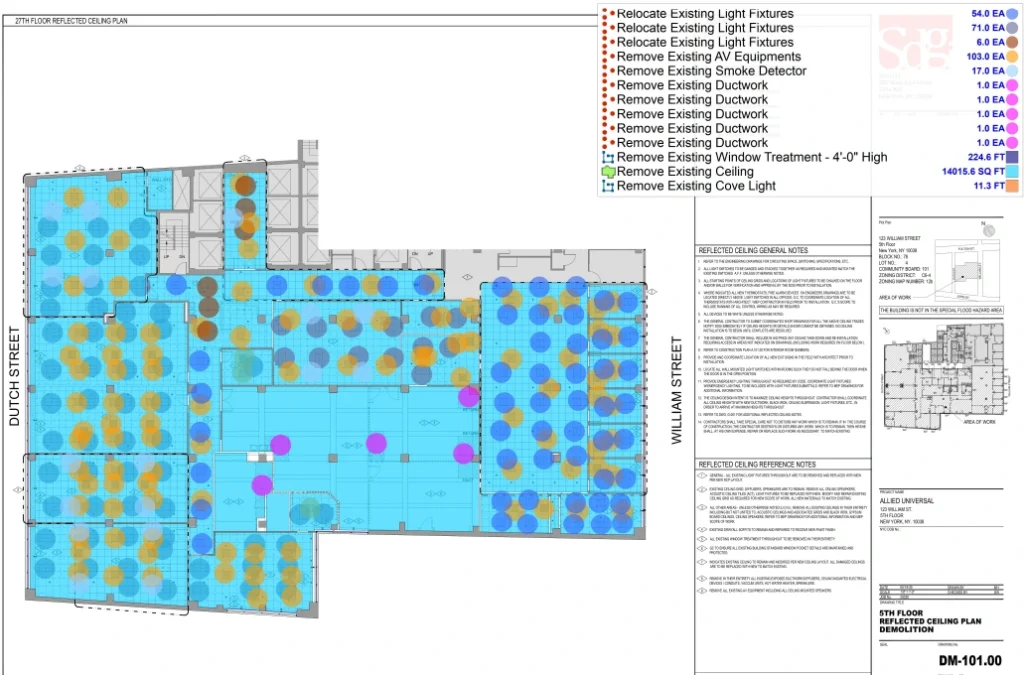

The demolition package came with two key plan sheets—DM-101.00 for the ceiling and DM-100.00 for the floor. Together, they outlined a complete interior teardown: ceilings, partitions, floors, and critical MEP systems. But this wasn’t just about ripping things out—it was the blueprint for transformation. Every line, symbol, and note held weight in building a precise, trustworthy estimate.

Quantifying the Demolition

The first task was putting hard numbers to the scope. Here’s what we pulled from the plans:

- Ceiling removal: 14,015.6 sq ft

- Flooring removal: 14,036.6 sq ft

- Electrical/low voltage removal: 1,154.5 sq ft

- Power poles removal: 865.1 sq ft

- Interior partitions: 404.5 linear ft (9′-0″ high)

These numbers aren’t just lines on a page—they dictate everything from labor hours to dumpster loads and disposal costs. Get them wrong, and the entire estimate unravels. Without precise takeoffs, you risk underbidding yourself into losses or overshooting with inflated quotes. Accuracy here isn’t optional—it’s the difference between chaos and control.

Tackling MEP System Removals

The plans’ color-coded legend revealed the complexity of MEP removals:

- Lighting: 254 fixtures, with a mix of “remove” and “relocate” notes—flagging opportunities for salvage savings.

- HVAC: Large ductwork systems crossing multiple zones, requiring sequencing before floor demo.

- Fire protection: FRP panels and protective banding removals—work that demands specialized crews.

- Electrical infrastructure: A full tear-out of security devices, AV equipment, and vacuum systems.

This wasn’t just pulling wires—it was surgical dismantling of systems integrated across the entire office floor.

Cost Implications

From an estimator’s lens, a few key insights stood out:

- Reuse vs. Replace – Relocating fixtures wasn’t just a design call; it meant real cost savings if done strategically.

- Skilled Labor Needs – AV, fire protection, and security systems demanded licensed trades, which drove labor rates higher.

- Waste Disposal – Metal, drywall, and flooring all required separate hauling, making dumpster counts and tipping fees a crucial part of the estimate.

Each of these influenced the bottom line—showing why demolition estimating isn’t “square-foot pricing” anymore.

Sequencing the Work

The plans also highlighted coordination challenges:

- Ceiling First – Demolition had to start at the top, with ceilings coming down before flooring removal to keep the process safe and efficient.

- System Shutdowns – Electrical and HVAC lines couldn’t just be ripped out; they needed a carefully sequenced shutdown and disconnection plan.

- Protecting Neighbors – With occupied spaces right next door, extra shielding was essential during ductwork and partition removal to avoid disruption.

For Mike, this project was never just about the dollars on a spreadsheet—it was about keeping operations running smoothly and reducing risk in the middle of a busy NYC environment. Cost mattered, of course, but so did control, safety, and minimal disruption in a building where every delay could ripple through dozens of tenants.

Risk Factors

Any estimator worth their salt knows the hidden risks can make or break a project:

- Unknown Conditions – What’s on paper doesn’t always match reality. Field surprises can change the game in an instant.

- Hazardous Materials – With an older building, the threat of asbestos or lead was always lurking, demanding extra caution.

- Urban Logistics – In the heart of NYC, tight access and strict disposal rules made even hauling debris a strategic challenge.

Identifying these risks upfront allowed us to price responsibly and prepare contingencies.

The Evolution of Demolition Estimating

This project highlights how far demolition estimating has come. It’s no longer about simply tearing everything out and trucking it away. Today, it’s a strategic process—breaking down materials, mapping the right sequence, calculating skilled labor needs, spotting salvage opportunities, and planning disposal with accuracy. Every element is measured, every decision backed by precision.

For Mike and Allied Universal, the estimate wasn’t just a number on paper—it became a roadmap for action. It gave clarity, cut down the risk of change orders, kept costs in check, and helped the schedule stay on track. In short, it turned uncertainty into confidence before the first wall even came down.

Final Thoughts–Demolition Estimating Services

Demolition might look like pure destruction, but for an estimator, it’s precision planning in action. At 123 William Street, every square foot, every duct, every light fixture carried meaning. By breaking it all down, we showed Mike and his team not just what had to be removed—but the safest, most efficient, and most cost-effective way to do it. That’s the true power of professional estimating: turning complex plans into a clear path forward.