Cincinnati Commercial Project

How do you accurately estimate a project with 74 isolated footings, 2,413 linear feet of continuous foundations, and three completely different building types—all while keeping costs under control?

The answer lies in the details. When we took on the E. Seymour Apartments project in Cincinnati, we weren’t just estimating concrete and rebar. We were orchestrating a financial strategy for 54,000 square feet of complex construction that demanded precision down to the last cubic yard.

The result? A multi-million dollar project delivered on budget, on schedule, and with zero cost surprises. Here’s exactly how we did it—and the proven estimation framework you can use to achieve the same results on your next major development.

Project Overview

Client: Kelvin

Project Name: E. Seymour Apartments

Location: Cincinnati, Hamilton County, Ohio

Project Type: Multi-Building Commercial Development

Construction Focus: Heavy Concrete Constructio

Project Scope and Scale

This project involved a multi-building complex comprising:

- Building 1: A commercial structure with over 18,000 square feet of concrete slab on grade and extensive isolated footings.

- Building 2: A heavy-duty industrial/commercial facility with nearly 24,260 square feet of concrete slab, dense reinforcement, and high-load foundations.

- Clubhouse: A recreational structure featuring 3,500 square feet of slabs and specialized footing widths (24″, 36″, and 72″).

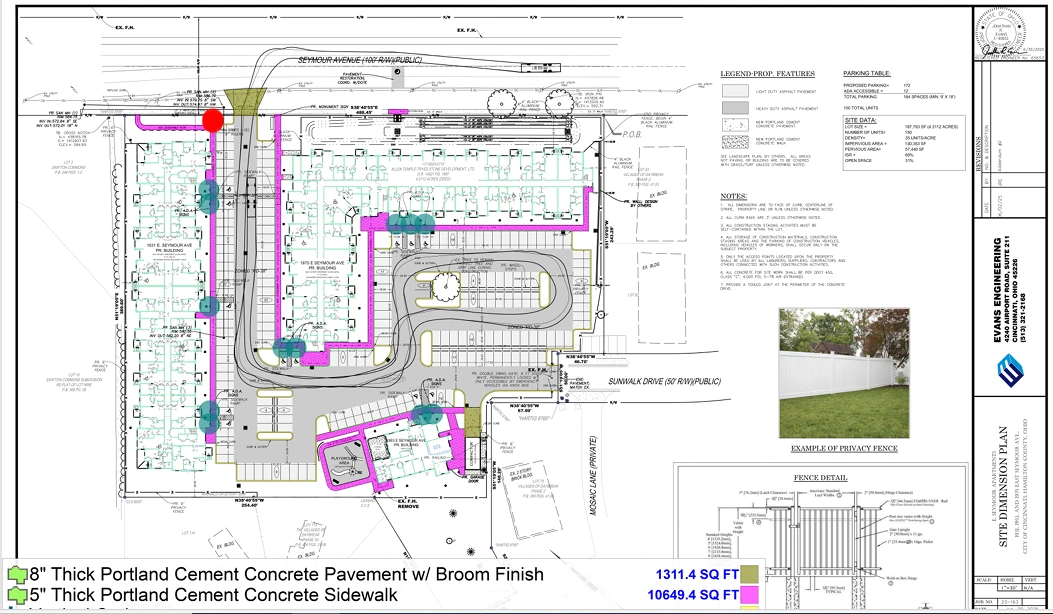

Beyond the core structures, this project pushed the boundaries of scale and detail. Think over 12,000 square feet of sidewalks, more than 1,300 linear feet of curbs, 9 sturdy light pole foundations, and a network of ramps, bollards, and stair slabs—each requiring precision down to the last cubic yard. In total, the site demanded 45,000+ square feet of reinforced concrete across multiple building types, making it a true showcase of complexity, coordination, and craftsmanship.

Foundation Engineering Analysis

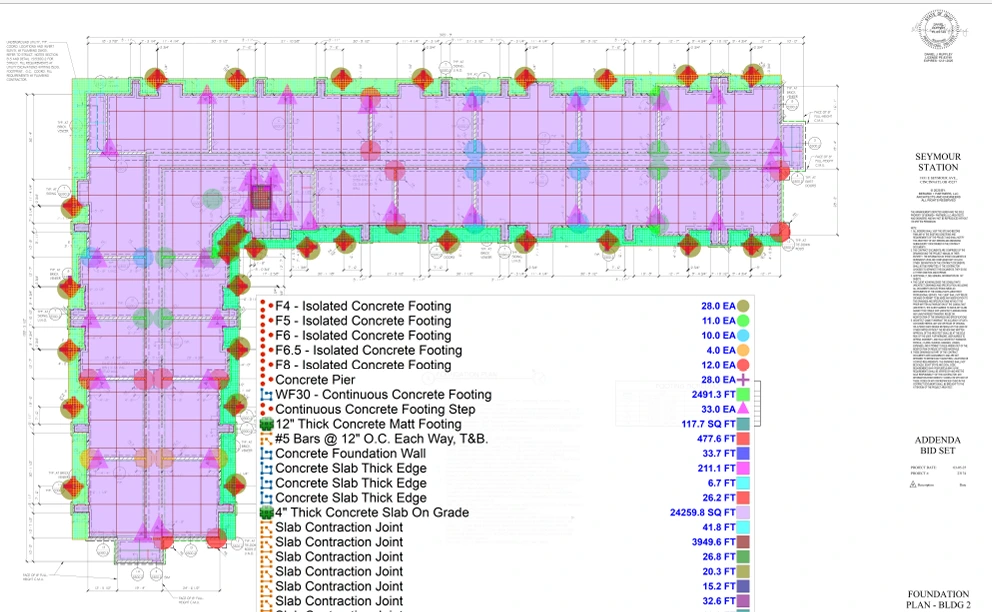

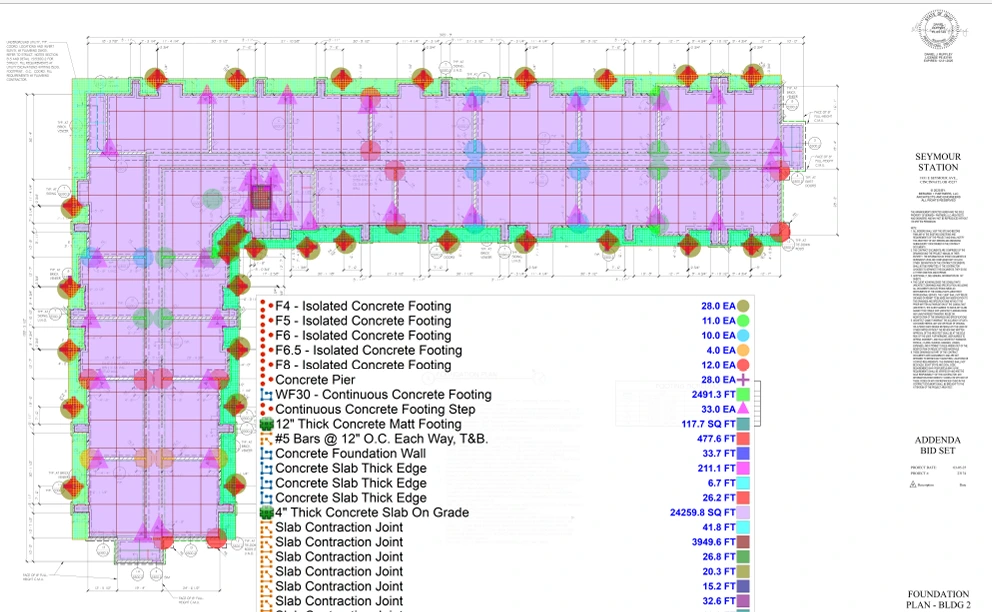

Building 2 – Industrial Strength and Load-Bearing Capacity

Building 2 was designed as a heavy-duty commercial/industrial facility, requiring:

- 74 isolated concrete footings for load distribution.

- 2,413 linear feet of continuous footings around the perimeter.

- A 12″ thick matt footing for high structural loads.

- A 24,259.8 square foot concrete slab on grade reinforced with #5 bars @ 12″ O.C.

The scale of this concrete work was nothing short of massive. With over 3,400 linear feet of contraction joints, heavy reinforcement density, and sheer volume, it quickly became one of the most cost-intensive and labor-heavy phases of the project. From an estimator’s lens, this stage alone required 300+ cubic yards of concrete—a critical backbone that shaped the entire project budget and dictated financial accuracy from day one.

Building 1 – Balanced Commercial Design

The scale of this concrete work was nothing short of massive. With over 3,400 linear feet of contraction joints, heavy reinforcement density, and sheer volume, it quickly became one of the most cost-intensive and labor-heavy phases of the project. From an estimator’s lens, this stage alone required 300+ cubic yards of concrete—a critical backbone that shaped the entire project budget and dictated financial accuracy from day one.

- 13,378.86 square feet of 4″ concrete slab on grade.

- 4,774 square feet of 6″ exterior slab, designed for heavier load-bearing areas.

- Numerous isolated and continuous footings supported by a standardized footing schedule.

Though less demanding than Building 2, Building 1 still required sharp estimation. Its wide foundations and mixed slab thicknesses called for precise labor, forming, and rebar calculations—vital for keeping costs accurate and the budget on track.

Clubhouse – Compact but Complex

The clubhouse brought a whole new challenge to the table with its irregular L-shaped design. At first glance, its size—just over 3,100 square feet of slab plus nearly 480 square feet of exterior slab—seemed manageable. But the varying footing widths of 24″, 36″, and 72″ quickly drove up complexity and unit costs.

This case shows how even smaller buildings can pack a big punch on the budget when irregular geometry and dense reinforcement details come into play.

Technical Highlights in Estimation

Across all three structures and site work, estimation had to account for:

- High-strength 4000 PSI Portland cement concrete.

- Wire mesh reinforcement and #3, #4, and #5 rebar in various zones.

- Broom finish pavement for slip resistance and durability.

- Concrete bollards, ramps, and stair slabs that required specialized forming and finishing.

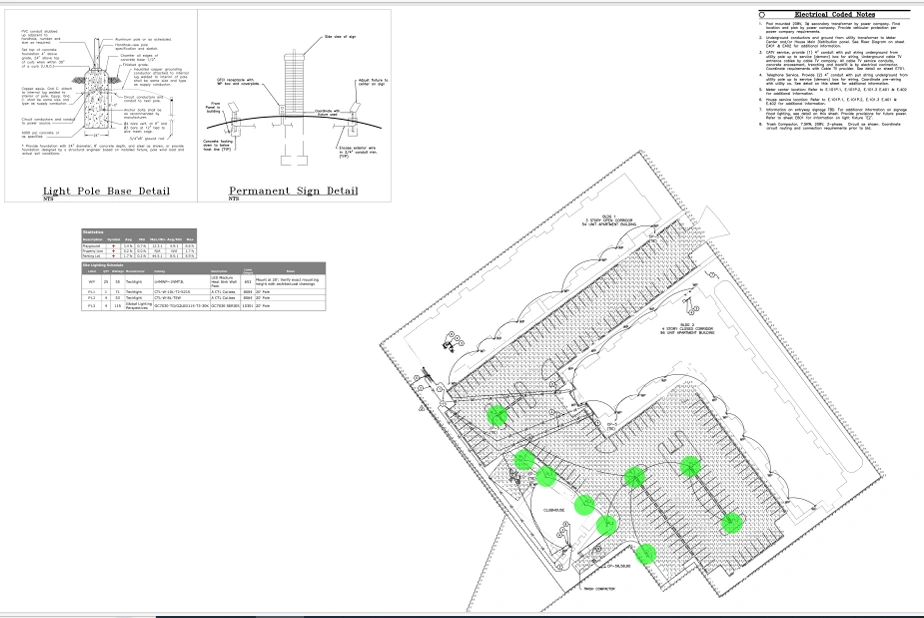

- Electrical/site infrastructure, including 9 reinforced light pole foundations and permanent sign bases.

Even the smaller components carried weight—each one adding extra labor, reinforcement needs, and sequencing demands. Overlook them in estimation, and you’re inviting hidden overruns that can quietly derail a project’s budget.

Site Development and Infrastructure

Beyond the vertical structures, the project required an extensive horizontal development plan. Estimation for site work included:

- Sidewalks: 10,649.4 square feet of 5″ thick concrete, which alone demanded meticulous quantity takeoff and cost allocation.

- Curbs: 1,376.2 linear feet of vertical curb and 1,074.8 linear feet of sidewalk curb.

- Driveways and Pavements: Over 1,300 square feet of Portland cement concrete paving, with broom finish for durability.

This phase delivered community-focused infrastructure—accessibility, circulation, and safety. Precision estimation of concrete, rebar, formwork, and finishing, while factoring drainage and landscaping, kept the project functional, safe, and on budget.

Cost Drivers and Estimation Challenges

- Concrete Volume: With over 500 cubic yards of concrete required, bulk ordering strategies were crucial to reduce unit costs.

- Reinforcement Density: Heavy rebar requirements in Building 2 increased both material costs and placement labor.

- Formwork Complexity: Multiple footing types and irregular clubhouse shapes raised forming costs beyond typical averages.

- Utility Coordination: Integration of electrical footings, sign bases, and site utilities required tight sequencing to avoid conflicts.

An estimator must carefully balance material costs, labor productivity, and construction timelines while also accounting for inflation. On top of that, they need to build in contingencies for risk factors such as weather exposure and soil condition variability to ensure the project stays financially viable and on schedule.

Risk Factors in Estimation

Any large campus project carries inherent risks. Key considerations included are

- Soil Conditions: Variable soil could increase footing sizes or depth, affecting concrete quantities.

- Weather Impacts: Extended curing periods during adverse weather could delay sequencing.

- Access Logistics: Multi-building construction required coordinated staging to avoid material delivery bottlenecks.

- Simultaneous Operations: Working across three structures increased quality control demands and labor scheduling complexity.

Thanks to detailed estimation and smart risk planning, the project stayed on budget and avoided costly surprises—proving how the right approach keeps builds running smoothly.

Optimization Strategies in Construction Estimation

Budgets are always under pressure from risks and cost drivers—but the real power of estimation is in stretching every dollar to its fullest potential. In this project, smart strategies didn’t just control costs—they turned challenges into opportunities, keeping the build on budget without ever compromising quality.

Bulk Material Procurement

With over 500 cubic yards of concrete estimated across all buildings, bulk purchasing wasn’t just smart—it was cost-saving. Ordering in volume cut unit costs, ensured consistent quality, and kept deliveries on schedule, making slab pours smooth and efficient.

Standardized Reinforcement

By standardizing rebar sizes and reinforcement patterns, labor hours dropped, installation became simpler, and material waste was minimized. A streamlined approach that delivered savings without sacrificing strength.

Efficient Forming Systems

For repetitive foundation elements like isolated footings, modular forming systems were the game-changer. Crews worked faster, reused materials, and maintained accuracy across multiple pours—all boosting efficiency.

Strategic Sequencing

Smart sequencing tied everything together. Coordinating site work, utilities, and vertical structures avoided costly rework. For instance, pouring sidewalks alongside light pole footings cut mobilization costs and kept the workflow seamless.

These strategies highlight how value engineering is more than a buzzword—it’s a game-changer in large-scale construction. Projects of this size demand more than just quantity takeoffs; they call for proactive cost management and seamless workflow integration to keep everything efficient, accurate, and on budget.

The Role of Technology in Estimation Accuracy

it’s about leveraging technology for accuracy and speed. On this project, digital blueprint analysis and advanced quantity takeoff software became the backbone of estimation, helping to:

- Identifying precise slab square footage across multiple buildings.

- Calculating linear footage of continuous footings with accuracy.

- Analyzing reinforcement placement patterns to avoid underestimating rebar needs.

- Integrating electrical and site work elements into the master estimate.

After using advanced tools, estimators reduced errors, accelerated the bidding process, and provided stakeholders with data-driven insights that improved confidence in the budget. In multi-building projects, even minor errors can snowball into major overruns.

Quality Assurance Through Professional Oversight

Another key pillar of this project was professional engineering oversight. Every drawing was stamped and certified by licensed engineers, guaranteeing full compliance with codes and standards. For an estimator, that’s a huge advantage—because it reduces risk, eliminates guesswork, and builds confidence in every cost projection.

- Structural details are verified before cost planning.

- Load-bearing requirements are documented, eliminating guesswork.

- Waterproofing, reinforcement, and finishing methods are clearly specified.

With this documentation in hand, the estimating team could lock in accurate unit costs and labor projections, creating a solid financial foundation that kept the entire project stable and predictable.

Conclusion

This case study proves how comprehensive construction estimation drives success in complex, multi-building projects. By breaking down foundation engineering, site work, reinforcement strategies, and utility integration, estimators kept finances aligned, risks controlled, and workflows efficient.

But estimation is more than numbers—it’s a strategic advantage. It safeguards structural integrity, ensures compliance, balances costs, and delivers lasting value for both clients and communities. No matter the project—industrial, commercial, or community-focused—accurate estimation is the true cornerstone of success.